Maxwell V2

The latest and greatest revision for my favorite personal money pit.

Utilizing industry connections, generous donors, engineering principles learned at UC Berkeley, and lessons from Maxwell, I was able to take Maxwell V2 to an entirely new level of performance and beauty.

2020

Maxwell

My solo high school capstone senior project. An entirely home-grown electric go kart with a top speed of 60 mph. Features a custom two speed transmission for both top speed and low end acceleration.

2018

Berkeley Formula Racing: B23

The first new car designed and produced by Berkeley Formula Racing since B20 challenger "Glass Cannon" in the 2019-2020 season. Designed to take the extremely competitive B20 and increase reliability and serviceability across the board, whilst completely uncompromising in performance.

2023

Berkeley Formula Racing: B20

My second year as part of Berkeley's Formula Racing team. I delve into my first year of aerodynamic and structural design for our package, as well as my second year of metallic and composite manufacturing. This time as subsystem lead.

2020

Berkeley Formula Racing: B19

My first year as part of Berkeley's Formula Racing team. I learn the ropes to a new form of manufacturing in that of composites and develop the skills to utilize the infrastructure the team possesses to create great pieces.

2019

Active Aero

Final project for ME100 (Electronics for the Internet of Things) offered at UC Berkeley. The motivation behind this project was to create a platform for active aerodynamics on Berkeley Formula Racing's single-seater vehicles for greater control of the aerodynamics of the car and ultimately more competitive lap times.

2020

Composite Impact Attenuator for a Formula SAE Chassis

This project explores the design and simulation of an impact attenuator constructed of composite materials that is smaller, lighter, and more aerodynamic than a traditional foam IA while still meeting all the regulations of the FSAE competition.

2020

FlexFix: Fatigue Detection Wearable

Final project for UC Berkeley "Augmenting Human Dexterity" course. Wearable device measures activity of the finger/hand and warns the user of overexertion/fatigue prior to the onset of pain.

2022

Coaxial Coplanar Rotorcraft

Final project for "Engineering Aerodynamics" course at University of California, Berkeley. Students were challenged to write code to simulate and optimize a coaxial coplanar rotorcraft and present their results.

2022

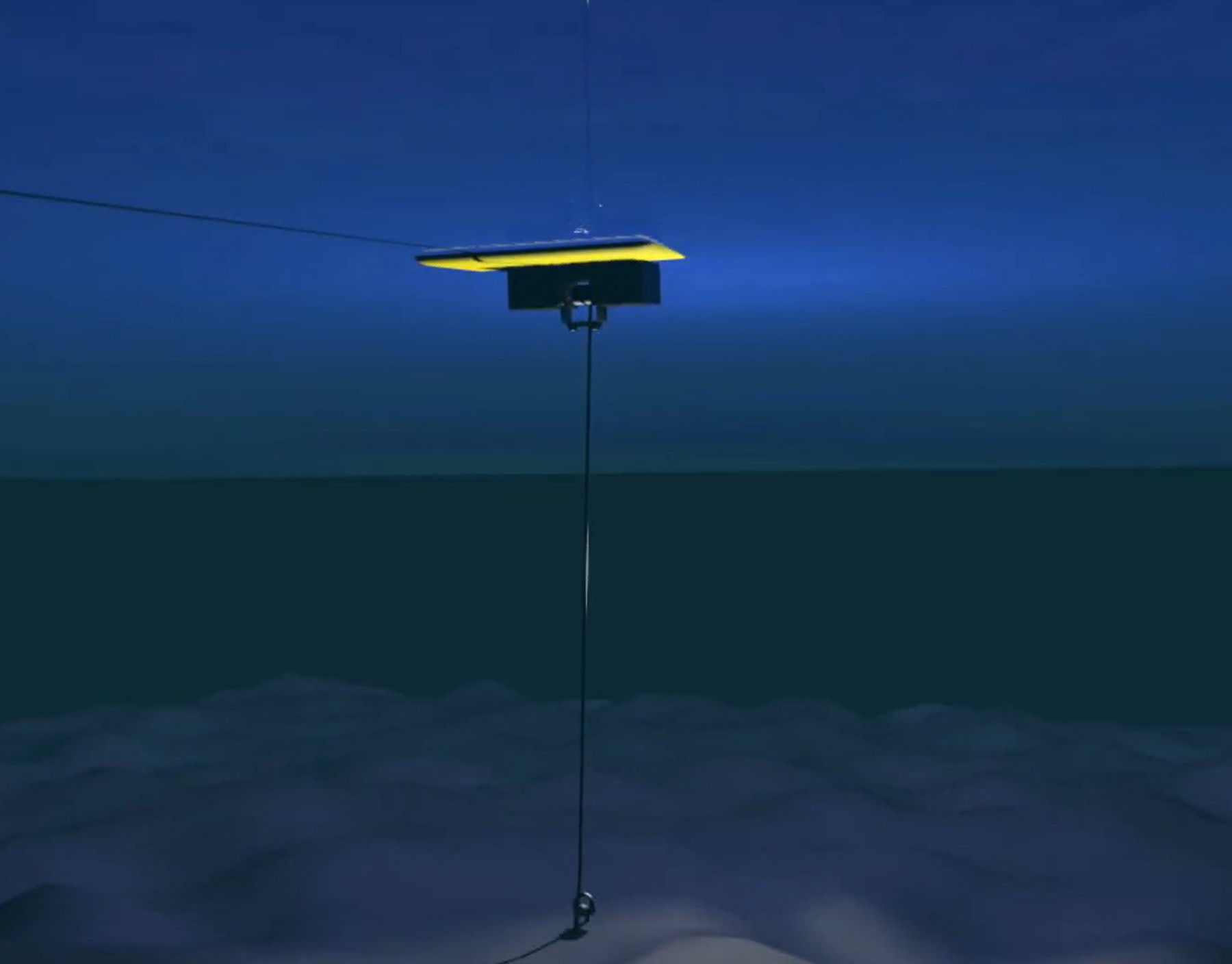

Animation: Mobile Ocean Wave-Powered Desalination Plant

Final project for UC Berkeley's Fall 2020 Engineering 128 (Advanced Engineering Graphical Communication) class, as well as video submission for the SDCal Desal lab competition.

2020

Miniature Wind Turbine

Final project for Berkeley's Three-Dimensional Modeling for Design (E26) class. Designed to win the competitions for highest stiffness-to-weight ratio as well as highest power generation.

2018

Flexipod

Final project for Berkeley's Manufacturing and Tolerancing (E27) class.

2018

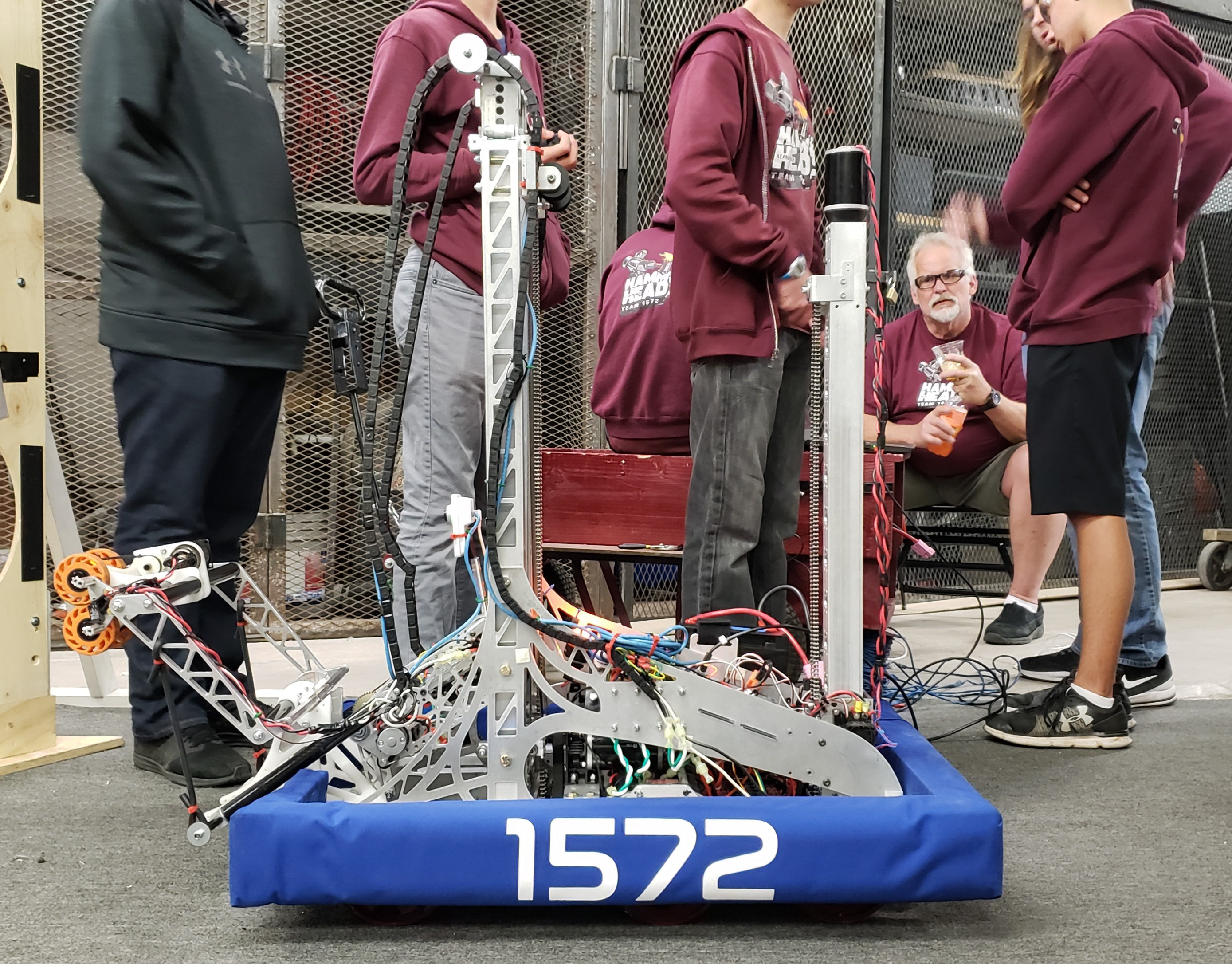

FRC: Komet

Robot for the 2019 FIRST Robotic Competition, Destination: Deep Space. I was a mentor this year, guiding students through design-for-manufacturing to appropriately leverage the resources of the team and its large machine shop.

2019

FRC: Gravity Hammer

Robot for the 2018 FIRST Robotics Competition: Power Up. This was my final year as a student, and certainly one of the most compact designs I have ever put together. Numerous design choices in this project were at their limits in terms of material failure in the pursuit of ultimate "lightweightness".

2018

FRC: Scorpio

Robot for the 2017 FIRST Robotic Competition, Steamworks. This was my first time I had such a large role in the team, where I ultimately found myself designing and wiring the entire robot. This year was incredibly valuable as there were plenty of mistakes I had committed that I have since learned from.

2017

FRC: Ghettobot

2016

MicroAire PAL-650 Cannula

This biomedical device is a seven piece assembly that I designed in conjunction with MicroAire Surgical Instruments as part of their Power-Assisted Liposuction (PAL) System.

2018

DCR Manufacturing Workholding Solution

A custom, yet standardized workholding solution for DCR Manufacturing's in-house Little Machine Shop Brand Benchtop CNC Machines to maximize productivity, ease of use, and precision over production of hundreds of thousands of needles.

2019

DCR Manufacturing Cannula Bending Solution

A highly adjustable, easy to use cannula bending solution that accommodates any diameter cannula up to 0.180" and any bend radius from 0.75" to 7". Has multiple sliding axes and fastening options for a wide range of repeatable bends for large production runs.

2017

MATE: Hammerhead

Underwater Remotely Operated Vehicle (ROV) for the 2017 and 2018 Marine Advanced Technical Education (MATE) Ranger Class Competition. Uniquely manufactured out of plate aluminum, using 6-thruster sensor input omni-directional movement, and a powerful compliant gripper attached to a 2-axis arm, this ROV was a stand-out at the competition. Now if only we could get it to be water-tight...

2018

NeoMotion

A compact omni-directional (can drive in any direction) robot with autonomous capabilities for following targets using vision processing and heat sensing technology.

2017

Vespa Top-Mounted Aero Fender Crest

Surfacing and work holding challenge for a 2-setup, 3-axis vertical milling center. Top mounted Selig S1223 airfoil with engraved name on the side produces several newtons of downforce for minimal performance gains for front end grip. At least it looks nice though.

2020

Sikorsky H-60 Floorboard Test Specimens

Machined 7075-T7351 test specimens for future Cold Spray mechanical testing. Manufactured several batches of varying complexity. The final batch required the revival of DCR Manufacturing's Cincinnati V.CNC 750 to machine larger floor board segments.

2020

Decorative Box

Goal: maximize volume of the box while minimizing usable volume. Joking aside, this project was an expression of 3D machining surfacing capabilities and experimenting with different materials for aesthetic appeal. Designed on SolidWorks, programmed with HSMWorks Ultimate, and machined on ProtoTRAK DPM RX2 RMX.

2020

Lumin

Kearny High EID Junior Capstone Project. Design a solar powered charging station. Whoever designs the best charging station has the opportunity to manufacture their solution. I did not want to manufacture this project (I was very busy with FRC, underwater robotics, and NeoMotion), so I designed the most absurd structure possible.

2017

Additional Projects

2020